Choosing the right overhead doors for your car wash can be the difference between profit and peril.

When it comes to building a new car wash today, the number one thing business owners are looking for is maintenance free operation.

Let’s face it, there is no point in setting up a “automated” car wash if you have to physically be there fixing it every single day!

A few years ago, we were contacted by a well-established company in Northern Minnesota for help on their new car wash being constructed later that year. As we spoke, they made it clear that they wanted the most automated, hands-free wash in town. After all, there is a heavy cost to fix doors and wash equipment, not to mention the negative effects downtime has on a busy day.

“Broken car wash equipment can destroy your reputation quickly, and those customers may never come back.” – Kevin Baumgartner, President of American Garage Door Supply

Before we get into the doors and operators, it’s important to know a few things about the conditions this particular wash facility faces every day.

When a customer reaches out to us, the first thing we do is talk to them about their specific building’s needs. In this case, we have a car wash in Northern Minnesota.

That means this facility, this equipment and these doors are going to be subjected to road salt, extreme temperature swings and nasty winds. Since our company headquarters is also in Northern Minnesota, we know full-well that Minnesotans like washing their vehicles at any temperature, even when it’s 30 below zero!

Step 1: The Doors.

We knew we would need an entry door that is nearly bulletproof for this wash to be functional and problem-free. There was no better option for them than our Survivor Series Polycarbonate Door.

This door features 5-X wall polycarbonate construction, which makes it extremely impact resistant. We’ve actually hit these panels with a splitting maul in our other videos and you would be amazed at how well it held up. As we all know, your entry doors take a beating from cars and weather alike, so it’s important that we give them the best chance at surviving possible.

We also went with a full vision panel in the center of the door. This makes it easy for customers to see if the wash is currently occupied, and it also lets in a significant amount of light. This customer has a color changing light system inside the building to match their marketing theme, and the see-through door section really allows that to shine.

Want to set up your wash facility for success? Fill out our contact form and we’ll be in touch right away.

American Garage Door Supply’s full vision center section allows light and visibility into the car wash bay.

Step 2: The Hardware.

You might think the door sections are the most important part of your door system, but really they are just the tip of the iceberg. What really ‘makes or breaks’ a door system is the hardware package holding it together. You see, a big mistake many wash operators make is choosing the wrong hardware for their building.

You could have the BEST door sections on the planet, and if they are held together by cheap galvanized hinges and exposed steel rollers you can guarantee a few phone calls per month from upset customers. Cheap garage door rollers probably cost business owners across the country MILLIONS of dollars worth of downtime annually due to their exposed bearing raceways and subpar materials.

Want to equip your door with stainless steel hardware? Visit our Stainless Garage Door Parts website!

As you look on the backside of this Survivor series door, you’re going to see our full line of Stainless Steel face hardware, complimented by our Magnum Supreme rollers to keep the door traveling through the track properly regardless of dirt and debris.

Stainless steel hardware keeps these doors moving properly without rust or corrosion issues.

Speaking of track, we opted for our proprietary Stainless Steel (2” or 3”) track on the wash bay entry door. If there is one thing our 30+ years of experience in the door industry has taught us, it’s that the underbody wash found on most wash facilities BLASTS the door with harsh chemicals numerous times per hour.

Due to the corrosive nature of the road salt in the winters and the chemicals used in the wash itself, this spray effect will absolutely ROT your door components in no time if you use improper hardware. Let’s be honest, nobody ever cleans their garage door track. Those harsh chemicals sit on the track 24/7 and can bring your operation to a halt when the rust sets in. Our Stainless Track eliminated that failure point entirely, and this customer could not be happier.

If you look up above the door, you’re going to see our Stainless Steel bearing plates, brackets and springs as well. Stainless steel springs provide a ton of life cycle advantages over galvanized and oil tempered springs, meaning less breakage and maintenance as the years go by.

Step 3: Choosing the door operator.

Now that you’ve seen the door system hardware, lets take a look at what gets this door moving day-in and day-out.

This is where it often gets tricky when it comes to the car wash world: The garage door operator.

You need to choose a door operator that is compatible with your wash equipment while also being safe for your customers and durable in these wet, nasty conditions as well.

For a long time, air powered operators have been considered the way to go in a wash facility. Electric operators have always struggled with the moisture, while pneumatic operators really don’t mind the wet environment as long as you take good care of the compressor and the seals inside the air operator of your choice.

That being said, there are some downsides to air powered operators as well. They lack customization, the door either goes all the way up or down with little in-between. They rely on a good, clean air source. This means you have an air compressor in the facility with it’s own maintenance schedule. Air compressors are loud, and if your building has office space inside that can pose an issue as well.

This particular building is set up exactly like that: It has a full office space with 8 employees on one half of the building, and the other half of the building is the wash bay and mechanical room. Let’s just say noise was a major consideration as we moved forward in this project.

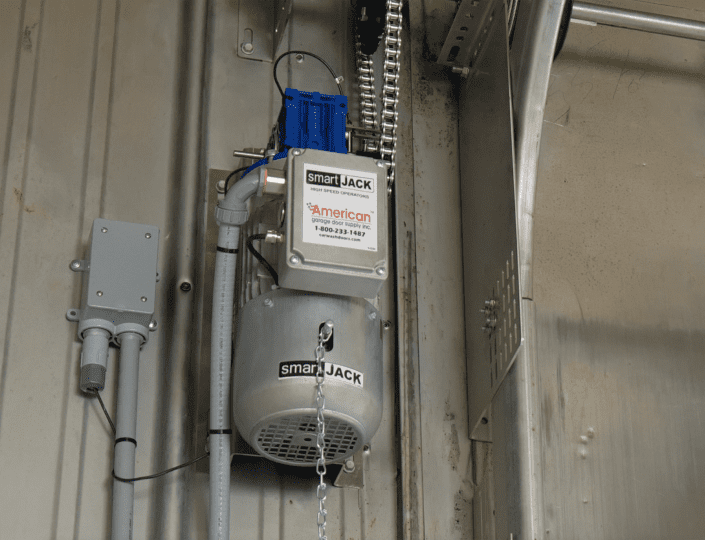

We wanted an operator that would integrate perfectly with the wash bay door, and wash equipment while also providing safety features to protect the business and customer’s property. We chose to install the SmartJack Operator.

The SmartJack is the newest commercial door operator on the market. It comes standard with advanced features that make it an ideal choice for wash bays.

The SmartJack is the newest electric operator on the market, and we have several videos going over the features of this particular door operator that you have to see.

It’s based on a variable frequency drive motor, which means it can be precisely tuned to your specific facility’s needs. With a completely sealed gearbox and NEMA 4x rated enclosure for the electronics, this operator was built for the harshest environments you can throw at it.

What really sets this operator apart is how customizable it is. Right off the bat, it comes with a slow start, slow stop feature that eases your door into it’s travel. This prevents shock loading and saves on wear-and-tear for ALL of your door hardware.

Since the door doesn’t slam to the ground, or hit the ‘open’ position with force, this operator is whisper quiet.

The SmartJack integrated seamlessly with the safety devices installed at this facility, and it also has collision detection built-in that will reverse the door if it somehow hits a trailer hitch or other obstacle.

As you can probably tell, there was a significant amount of planning and coordination involved in constructing this wash facility up for hands-off operation, but the results are well worth it. Other than topping off the wash bay chemicals and basic upkeep, this facility keeps on turning a profit even on the harshest winter days.

Having spent well over 30+ years in the specialty door industry, we have learned all of the tricks when it comes to setting up these facilities for success. It doesn’t have to be new construction either, we can help you outfit your current building to both reduce downtime and increase profitability.

We help business owners just like you every single day, and would love to do the same for you. Fill out our contact form OR give us a call at 1-800-233-1487 and let our experience go to work for you.